Precision parts refer specifically to the metal processing category in the parts industry that requires high precision. "Precision" means tolerances within 0.05mm. Including precision plastic parts, precision stamping parts, precision turning parts, etc., commonly used in electronics, watches, aviation and other industries.

Precision metal products, precision metal processing, high-precision CNC machining, precision metal stamping, precision metal processing plants, precision metal parts, precision lathe processing, high-precision CNC processing plants, CNC precision machining, precision parts

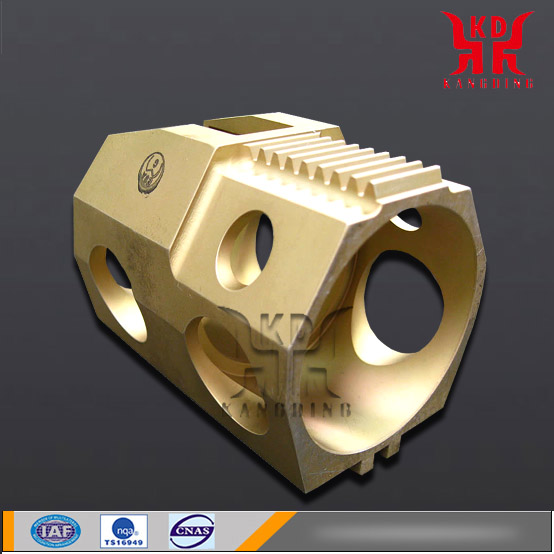

Precision stamping

Types and Technical Features of High Speed Precision Stamping Parts

High-speed precision stamping parts can be divided into electronic parts and IC integrated circuit lead frames according to industry, use and process characteristics. Motor cores, Electric core class, Heat exchanger fins, automotive parts, home appliance parts, and other types.

Parts mainly include connecting devices, connectors, brush parts, electrical terminals, and elastic parts.

High-speed precision stamping technology involves many fields such as machinery, electronics, materials, optics, computers, precision detection, information networks, and management technologies. It is a multidisciplinary system engineering.

Precision motor core

The iron core is an important part of the motor product, generally made of 0.35mm, 0.5mm thick silicon steel sheet. In all aspects of motor production, core punch production is the key. At present, China's high-speed precision stamping iron chips and iron cores are automatically riveted, Three cores with twisted slot rivets, Iron core with twist groove and rotary rivet, Core double-turn rivets, iron double-row rotary rivets, Large outer rotor core with twisted slot rivets, Stator core semicircle combination riveting, Stator core multi-piece stack riveting, The combination of high-speed precision stamping production technology such as long straight-bar stator core coils and stacking rivets is not inferior to international advanced technology.

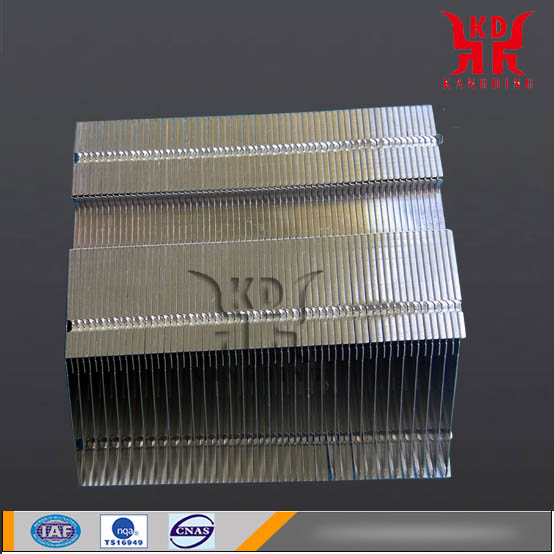

Precision heat exchanger fins

The fins are the main components of air conditioning products and are generally made of 0.105mm thick aluminum foil. In recent years, China has significantly improved the production technology of high-speed stamping heat exchanger fins, such as domestic air conditioning heat exchanger fins, Automotive air conditioning heat exchanger fins, Industrial air-conditioning heat exchangers, integral duct air conditioner heat exchanger fins, The high-speed precision stamping production technologies such as the new-type pore air-conditioning heat exchanger fins and the large-scale cold-storage radiator fins have reached the international advanced level.

Precision IC Lead Frame

Lead frame is the carrier of discrete devices and integrated circuits. The chip carrier lead frame as a semiconductor device is mainly characterized by many types, large batches, high precision, small shapes, thin materials, partial plating on the surface, and strict appearance requirements.

Precision turning parts

Contemporary precision ultra-precision machining technology is mainly used in aviation, precision instruments, computer industry and optical industry.

For example, a computer disk has a flatness requirement of 0.1 to 0.5 μm and a surface roughness of RaO.O03 of 0.05 μm.

The X-ray astronomical telescope used for celestial bodies has a maximum diameter of more than 1 meter and a length of 0.6 meters. The dimensional accuracy requirement is 1 micron and the surface roughness is Ra 0.05 micron.

For optical components used for UV and X-rays, the surface roughness is usually Ra 0.001 micron. Commonly used inertial instrument air bearing gyro inside and outside support ball and roundness of 0.2 to 0.6 microns, size accuracy of 0.6 microns, surface roughness Ra0.012 a 0.05 microns.

The laser gyro plane mirror has a flatness of only 0.03 μm, a surface roughness Ra of less than 0.012 μm, a mirror for laser fusion, a multi-faceted prism for detecting the index accuracy of a rotary table, a cartridge for a copier, and a video recorder. Magnetic heads, optical disks, and silicon chips used in large-scale integrated circuits for computers have extremely high requirements for surface roughness and dimensional accuracy.

With the rapid development of industries such as automotive, energy, medical equipment, information, optoelectronics, and communications, the demand for ultra-precision processing machines has increased dramatically.

Applications in industry include aspheric optical lenses, Fresnel lenses, ultra-precision dies, disk drive heads, disk substrate processing, and semiconductor wafer cutting.

During this period, related technologies of ultra-precision machining equipment, such as controllers, laser interferometers, air bearing precision spindles, air bearing rails, oil bearing rails, and friction-driven feed shafts, have also gradually matured, and ultra-precision machining equipment has become Industrial production machinery and equipment, even small companies, have also introduced mass production equipment.

In addition, the precision of the equipment is also gradually approaching the nano level, the machining stroke becomes larger, and the machining applications are gradually widened. In addition to diamond lathes and ultra-precision grinding, ultra-precision five-axis milling and fly-cutting technologies have also been developed and can be Non-axisymmetric aspheric optics are machined.

Precision machining technology

Ultra-precision cutting, such as diamond cutting tools for ultra-precision cutting, can process a variety of mirrors. It has successfully solved the processing of large parabolic mirrors used in laser fusion systems and celestial telescopes;

Ultra-precision grinding and grinding processes such as high-density hard disk coating surface processing and large-scale integrated circuit substrate processing;

Ultra-precision special processing: such as the graphics on large-scale integrated circuit chips, is processed by electron beam and ion beam etching. Such as scanning tunneling electron microscope (STM) processing, line width up to 2 ~ 5nm.

(1) High precision. Including high static and dynamic accuracy, the main performance indicators are geometric accuracy, positioning accuracy and repeated positioning accuracy, resolution, such as spindle rotation accuracy, rail movement accuracy, indexing accuracy, etc.;

(2) High stiffness. Including high static stiffness and dynamic stiffness. In addition to its own stiffness, it should also pay attention to the contact stiffness, and the stiffness of the process system composed of the workpiece, machine tools, tools, and fixtures.

(3) Highly automated. In order to ensure the quality of processing and reduce the influence of human factors, the processing equipment is often automated using a numerical control system.

In the aviation industry, there are a lot of demand for precision and ultra-precision machining in the manufacture of artificial satellites, space shuttles, and civilian passenger aircraft. For example, attitude bearings and telemetry components for satellites have a great influence on the observation performance. The bearing is a vacuum non-lubricated bearing, and the surface roughness of its hole and shaft is required to be Ry0.01μm, ie 1nm, and its roundness and cylindricity require nanometer precision.